Gadwal, in the state of Telangana is considered world famous for the handloom zari sarees. The local weavers are highly skilled wherein more than 5 meters of saree fabric could be folded to fit into something as small a match box. Gadwal Sarees are highly popular for many decades.

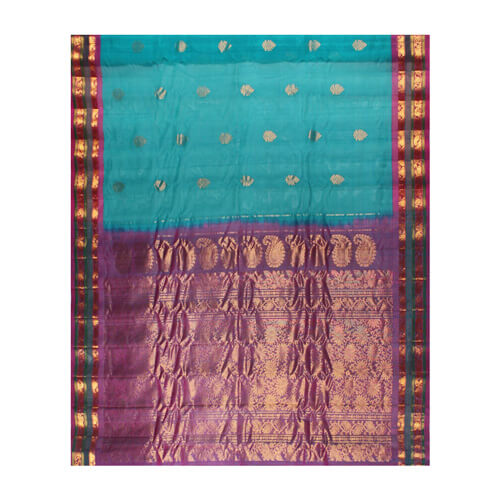

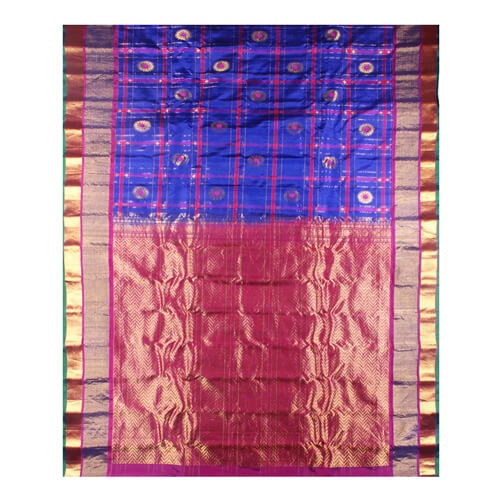

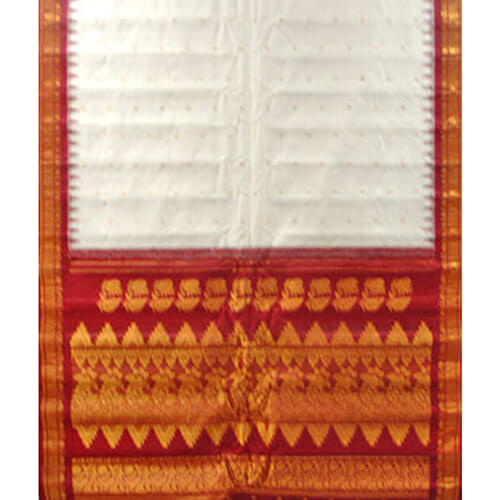

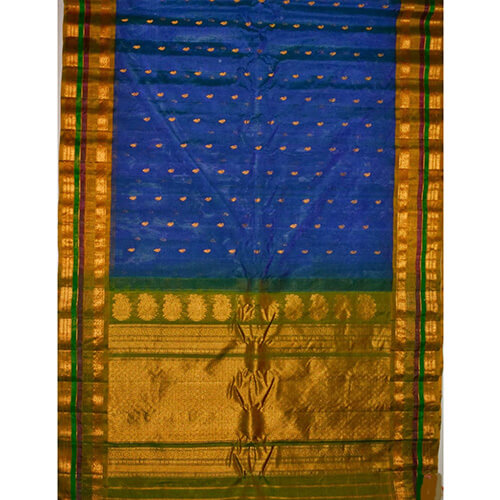

The historic town is known for its characteristic cotton sarees that come with an attached silk border as well as silk pallu. The materials used in manufacturing Gadwal handloom sarees are Silk / Cotton and Zari. The silk border is made of Tussar or mulberry and the body is made using unbleached cotton. There is even colored cotton or silk checks used. Weavers also make pure silk models of Gadwal sarees.

Gadwal handlooms are quite popular for the durability of the various colours that are used in the yarn. The mixture of these colours gives the durability. The count used in weaving technique results in the softness as well as the hardness of the fabric. The speciality of each and every thread used in Gadwal saree is that it is hand woven.

For each saree, 4-8 days of efforts by two weavers is required. The process of making a Gadwal Saree starts with the process of dyeing silk or cotton yarn. Dyeing is a colouring process achieved by dipping the yarns in boiled color water at a very high temperature. The colours are applied based on the specification by weavers and orders from customers.

After drying the yarn in shade, it is then rolled over small sticks and finally converted to thread. The yarn is now loaded as warp into the loom for the actual process of weaving. Gadwal Sarees are woven traditionally according to the interlocked-weft technique (Kuppadam or Tippadam) or Kotakomma (also called as Kumbam) with respect to the design of the borders. Hence these are also known as Kotakomma or Kumbam sarees.