Handloom Tradition with a Great Legacy!

Narayanpet region in Mahbubnagar district of Telangana is renowned for its exquisite and unique cotton handloom and silk sarees, which are widely popular. There is a historic legacy behind the handloom industry of Narayanpet. It is said that the famous Maratha king, ChatrapatiShivaji Maharaj had once travelled to this region where he rested for some time before continuing his journey while few weavers from his entourage, had actually stayed behind. It is these weavers who reportedly brought this tradition here of weaving sarees with a district design, which later came to be known as the Narayanpet sarees. Therefore, a clear Maharashtrian influence can be observed in these sarees.

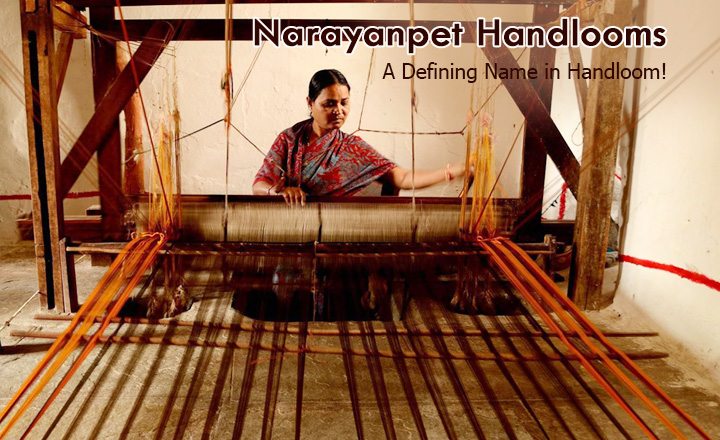

Process of Handloom Making

The making of handloom sarees here can be described as a unique process wherein eight sarees are made in one go on the loom. Therefore, instead of standard 7 yards of fabric which are generally mounted on the loom, about 56 yards of Silk are mounted, all at a single time.The process of making each Narayanpet handloom saree begins with dyeing of the silk/cotton yarn.

Dyeing is a process where the yarn is dipped in the boiled color water at a very high temperature. This process ensures that the color is spread uniformly all through the yarn while unaffecting the quality of the yarn being used.The process of colouring is a crucial step and the yarn is dried under the shade and not under the sun.The dyed and dried yarn is finally loaded into the loom for the final process of weaving. The weavers here easily make 30 sarees out of one beam of warp.

The sarees of Narayanpet have a characteristic checked surface design with embroidery while the border or the pallu features intricate ethnic designs. Narayanpet handloom sarees usher a contrasted look with the small zari designs. The borders and pallus of Narayanpet handloom sarees are very traditional, characterized by a rich pallu as well as a unique pattern of attractive and alternating red and white bands. The border is accompanied by a flat stretch of deep maroon, chocolate red or red colour.

There are double-shade sarees too, featuring blends like pink-purple and maroon-mustard. It has always been a cherished desire of women to choose sarees that are special and exclusive. They find happiness in selecting their desired saree type, and handlooms are always chosen for their durability and attraction. There is a great demand for the handloom sarees of Narayanpet and apart from the main town, there are several villages in the region where hundreds of weavers’ families are dependent on this tradition for their livelihood. These sarees are usually worn by women during special occasions, reflecting elegance and rich look. It represents a rich legacy of Telangana Handlooms in India.

In this process, initially the hollow casting is used for making a clay core that would define the way the object is created. The core is further filled with bee’s wax and resin etc. This wax is further shaped while finer details are made with proper embellishments. This task is mainly dependent on the carver’s skill, which is then covered with clay and there are drains made on the mould to see that the wax is drained after the mould is heated. The wax is replaced next by molten brass, gold, bronze or silver which is left for hardening inside the mould. The mould is subsequently chipped away for retrieving the object inside. Finally, it is polished and the finished product is put on display.