Art Work, That Enhances Interior Decoration

Carpets are used for many purposes, right from insulating one’s feet from cold tiles or concrete floors, to making a room comfortable to sit on the floor, apart from adding an element of decoration to a room. Carpets can be created with any color, based on the differently dyed fibers used. There are many patterns and motifs used for decorating the surface.

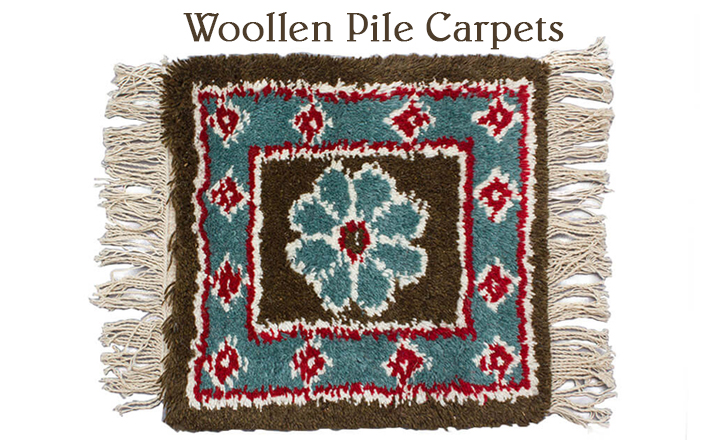

Carpet making has been in practice since hundreds of years in India while the influx of Persian and Moghul culture lent a completely new way of carpet making and innovating, which continues to this day. There are many hand-made items and attractive interiors which have always been a key element of interior decoration. A carpet is usually a textile floor covering which typically consists of an upper layer of pile that is attached to a backing. The piles are traditionally made from wool.

Process of Carpet Making

Carpets are usually produced on a loom which is similar to the ones used for woven fabric. It is made using needle felts, which are knotted by hand with their pile injected into a strong backing material (a process called tufting). These are then flat-woven, made by hooking the wool through the meshes of a sturdy fabric material or embroidered ones.

Wool is a commonly used material to make carpets due to its excellent durability, and the ability to get dyed easily. It is also available abundantly. Blended wool yarns are being used extensively for the production of modern carpets, with the blend ratio being 80 % wool and 20 % synthetic fiber.

Raw Materials Used

Carpet are made of dyed pile yarns where these yarns are sewn while a secondary backing gives more strength to the carpets. The adhesives bind the primary and secondary backing materials while there may be a cushion also laid underneath the carpets for a much softer and luxurious feel.

Preparing the yarn

Wool yarns are procured by the carpet manufacturers either in the normal fiber form or bulk. Most of these are loose, individual strands which arrive in bales. Many bales are blended together forming one batch into a hopper. Following lubrication, they are further spun into long and loose ropes using a carding machine. These are further pulled, then straightened, and finally spun into single yarn which is wound onto the spools. The process of heat setting helps the yarn to maintain its shape.

Dyeing of the yarn

Most of carpets are dyed after the process of tufting, while some yarns are dyed first. The treated dyes are circulated into the yarn through the bath, or by passing yarn through the vats of dye. There are few heated dyes which is added under pressure. In some instances, yarn is knitted onto a form which is further printed with dyes before this yarn is unraveled. Finally, the dyed yarn is steamed, washed, and subsequently dried.

Tufting the carpet material

The dyed yarn is now put on a creel inside a tufting machine, which is then fed into a tube, leading to the tufting needle. The needle pierces into the primary backing, pushing the yarn down into a loop like structure. A looper seizes and then releases this loop of yarn even as the needle pulls back up, which is done repeatedly. Each tufting machine produces several hundred square yards of carpet every single day.

Dyeing of the tufted carpet

The standard roll lengths is now fed into a vat filled with water. It is initially heated before the dyes and chemicals are further mixed. This mixture is brought to a boil and made to heat for many hours. After the process of dyeing, the carpet is again steamed so that the color is fixed and any excess color is washed off. The resulting carpet material is dried and placed on a roll.

The Finished Product

The ends of this dyed carpet are sewn together forming a continuous belt. This belt is later rolled under a dispenser which spreads a coating of latex to the bottom of these carpets. The carpet is finally placed in an oven for curing the latex. The completed carpets are steamed, and then brushed, vacuumed, and run through a special machine which eliminates any tufts which rises above its clear uniform surface. The carpet is then rolled into various lengths, packaged and shipped to warehouses or retail carpet stores.